In addition to automotive technologies, we continued our activities to increase our market share in the white goods and defence industries.

Starting production in 1970 with two machines in a small workshop, AL-KOR has been producing moulds and serial parts for 51 years for many sectors, especially the automotive and white goods sectors, in production facilities equipped with the latest technology in Istanbul and Bursa. We talked to Mr. Berç Darçin, Chairman of the Board of Directors of such a well-established brand, about AL-KOR's activities in 2021, pandemic measures, investments in digital, sector views and 2022 targets.

How was 2021 for you and what did you experience?

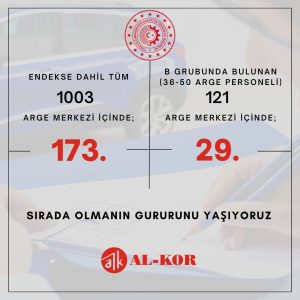

2021 was a year of developments in many different dimensions for Al-Kor; we had a period in which electronic-mechatronic products were added to our metal-plastic component product portfolio, in which new generation products that we completed the R&D phase started to be commissioned. Managing the disruptions in the global supply chain, keeping up with the semiconductor-related order fluctuations of our main industry customers, and of course, most importantly, maintaining our ongoing investments have been our main focus. In addition to automotive technologies, we continued our activities to increase our market share in the white goods and defence industries. Yıldız Technical University Alternative Energy Systems Club, in which we take part in our social responsibility projects with the aim of expanding our work with regional Vocational High Schools to Universities, made us proud by winning the first prize in TÜBİTAK Efficiency Challenge 2021 with Lyra and Hydra vehicles, of which we are one of the sponsors.

What measures have you taken with the pandemic?

We continued our activities in a working order that will protect the health of all our employees with the priority of fulfilling the requirements of the pandemic within the dynamics of the manufacturing industry. While going through processes in which applications were made specific to the departments in both remote working and flexible working order, we managed to be an agile organisation in many dimensions without any interruption in the production and shipment of the products of our global customers. We minimised our risks with the use of personal protective equipment and hygiene measures that entered our lives with the pandemic, as well as outsourced services.

What kind of investments did you make during the transition to digital?

Our need for digitalisation in terms of Business Management is greater today than ever before, in the event that processes and processes are not digitalised at the right points during the growth of organisations, the sizes turn into uncontrollable kits, causing the steps to be taken afterwards to be both longer and costly. In this context, it has reached the final stage of my project to digitalise all dimensions from customer quotations to project management, from production data to financial outputs. Since we have horizontally integrated technologies, it is obvious that our project, which will provide great contribution and efficiency in achieving ideal synchronisation, will contribute to the achievement of our company's goals in the medium and long term. What would you like to say about the sector? Unfortunately, the automotive main industry will complete 2021 by shrinking as in the past Global crises, but more importantly, the transformation speed of the sector is accelerating as much as possible. In order to keep up with this transformation and be a part of the global game, it is obvious that we need to be prepared for electric-hybrid-autonomous vehicle technologies. For the last two years, Al-kor has been keeping pace with the development wind of the sector by intensifying its strategic investments in this framework and continues to gain both new products and new customers. This is why we have a lot to say in these days when it is seen that those who produce conventional products will not have a say in the future of the sector.

Have you experienced an increase in sales and export figures compared to the previous year and what are your targets for 2022?

Despite the contraction in the global market compared to last year, our ability to grow by 10 per cent on a foreign currency basis and increase exports by 14 per cent will result in a much better performance in the coming years in parallel with the development of the market. Despite many global and local uncertainties, we plan for our company to grow by 15 per cent on a foreign currency basis in 2022, within the framework of the works taken and contracts concluded. We can herald that we will see the sales unit price reach a level well above the sector average in the ratio of sales unit price to weight, especially with the increase in the share of high value-added electronic-mechatronic products in turnover.